Dear Readers of permanent façade access blog by Rostek! Let me introduce myself: My name is Mikko Peltonen and I’m one of the newest additions to Rostek crew. I began as the COO in late November and found myself in a well-organized company with common ways of doing things. As I learned more, it turned out that Rostek had implemented ISO9001:2015 Quality Management System (“QMS”) in 2017 and the process-driven way of working was – and is still being – rooted in the day-to-day operations.

Co-operation and innovative thinking combined with structured process management lead the way to quality and success.

Co-operation and innovative thinking combined with structured process management lead the way to quality and success.

Quality Management System to guarantee client and employee satisfaction

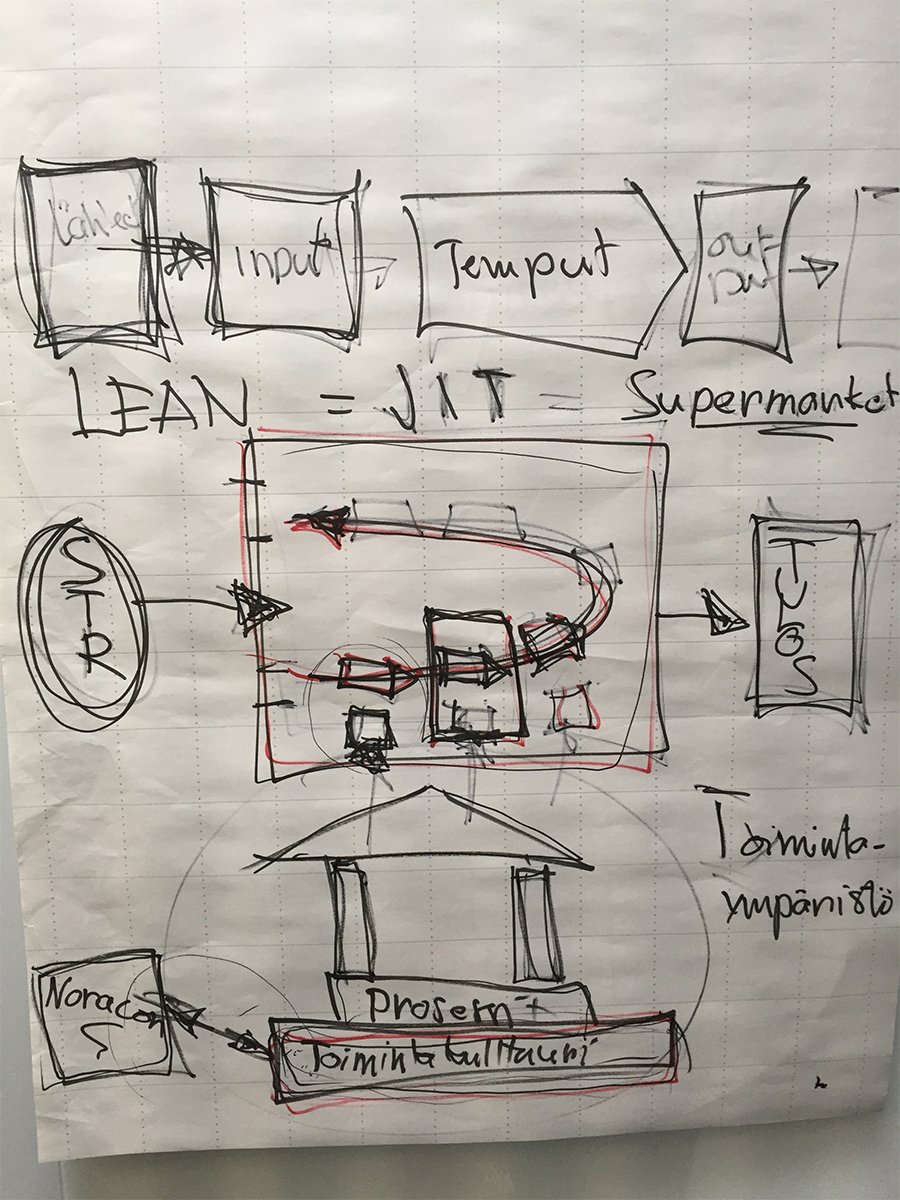

For me as a new employee, it was impressing to face new employee induction program which was also part of the QMS implementation resulting in well-thought and -documented steps to familiarize myself to organization and business. For Rostek’s clients this is even more important: As we design and manufacture facade access systems to most complex buildings worldwide, our clients can trust that our work is driven by quality, systematical processes and risk-evaluations.

We work as one company rather than a group of people doing their things in their own way. International Organization for Standardization - Iso.org (https://www.iso.org/iso-9001-quality-management.html) says it right: Using ISO 9001:2015 helps ensure that customers get consistent, good quality products and services, which in turn brings many business benefits. This what we believe as well!

|

|

| Teamwork to find the best possible QMS for Rostek. | As end result, we comply with the standard. |

My second month in a new job put Rostek (and me!) to an acid test: It was time for annual ISO9001:2015 audit by German-based but international inspection and certification firm Dekra. The audit day was highly interesting to understand our level of ISO9001:2015 compliance. The result was that we comply with the QMS very well! Great job Rostek team!

As you all know, quality and process-driven management is merely a marathon rather than sprint race or a one-off project. The next step in our continuous development pipeline is to digitalize our internal quality defect process in order to identify possible defects as soon as possible, fix them and especially fix the root causes beyond them. The aim of this boils down to our key target: Ensure consistency, quality and safety for our clients worldwide!

All the best and look forward to co-operating with you in the future,

Mikko