Window cleaners working at the highest levels of the building are considered to be some the bravest people alive. This work is often considered to be dangerous. That used to be the situation when the rules and regulations for window cleaning were not that high. We at Rostek value the life the people using our equipment. Therefore we follow all the general standards and norms. Sometimes we go and exceed them, if we believe there could be some problems. By working safely and not cutting any corners we can proudly say that there have never been any fatal accidents caused by faulty products or proper use of our products. That is a good record for a business that started in a business sector that was not a safe one.

Here we have listed the normal safety features we have in our facade access products. These are only the general features, any extra features are welcome if required by the project or by local legislation. This list can be freely used for your reference, or if you want to have safe specifications for your project. If there is anything missing from the list or something you disagree, please contact us!

BMU Cradles – Suspended Access Platforms

Double wire system

For each hoist there are double set of wires. This means that if anything would happen to the lifting wire, there is a safety wire that will prevent an accident.

Automatic slack wire safety device

Each hoist is fitted with an automatic slack wire safety device which acts on the safety wire. The slack wire safety device will lock onto the safety wire if the lifting wire loses tension or breaks.

Top limit switch and ultimate top limit switch

When going up there is a top limit switch which will cut the up-control circuit only. When the top limit switch is operated the platform can be driven down but not up.The ultimate top limit switch comes into operation if the top limit switch fails and cuts the control voltage.

Bottom limit trip bar

In case of the platform hitting an obstruction when driven downwards, the limit switch cut the down control circuit only. The platform can be driven up but not down.

The design of the cradle prevents rocking of the system too much

The position of the wire drums keeps the center of gravity low together high stabilizing bars makes the platform steady even when people walk on the platform.

Electromechanical overload switch

Both hoists are equipped with an electromechanical overload switch. The switch is set up to trip if the load on the hoist is 25% above the safe working load. The platform cannot be driven up when overloaded. Overload warning stops the movement and secondary overload device, the motor is designed for the weight.Also the hoists are limited according to the project specifications not to lift more than required. This means, if there is too much overload, the cradle will not move up.

Safety harness attachment point (Lanyard fixing points)

There are two fixing points for safety harness, so that the user can fix himself to the cradle. These fixing points are not required by any standard but most the users want to use them

No-power descent system

In the event of power failure the platform can be lowered at a controlled speed (which should not exceed 6 m/min) by manually opening the electromagnetic brake mounted to the end of the hoist.

Lifting with hand wheel

The system can be driven up also manually. This is very slow and therefore used if it is needed to go up few centimeters, for example to reset the safety device.

Emergency stop button

Emergency stop button to turn off all the electric power in the cradle

Phase protection relay

All platforms built to suit a three-phase power supply are fitted with a phase protector. In the control box cover, there is a warning light which is on, in case of incorrect phase sequence.

Closed cladding

The cradle has closed cladding and closed floor. This prevents any small items from falling out from the cradle. For example tools and washing materials easily fall out if there are no claddings.

Wall restraint system

If the lifting height is over 40m a restraint system is needed to keep the cradle close to the wall. A restraint point is needed every 20 meters after 40 meters has been lifted from the ground.Height meter to stop the cradle at agreed heights. This will help to know when to hook into the restraint system. This is usually delivered only at a request

Wind speed

The system is usually not allowed to be used if wind speed is over 14 m/s, this can be higher or lower in depending on the local regulations.A wind meter can be attached to the cradle. The wind meter can be used to automatically stop the use of cradle or only to give a reading.

Wall rollers and buffers

The wall rollers and buffers prevents the platform from spinning and swaying. This will also minimize the risk of damage to the facade of the building

Carry-on weight

For reasons of safety and ergonomics, it is not recommended that items in excess of 25 kg in weight be handled by persons when working from a suspended platform

Testing

Every cradle is tested on the factory and separate on site testing before commissioning is required (with a 25% overload)

Only in BMU2 cradle, (Two hoist suspended platform)

Anti-tilting system (Self-levelling system) to stop tilting over 10 degrees

The platform is equipped with an automatic self-levelling system, which stops one hoist and allows the platform to re-level before re-starting the hoist that was stopped

If the automatic self-levelling system fails, there is a mechanical device at 14 degrees to prevent it from tilting too much.

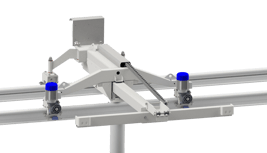

All motorized trolleys

Limit switches

Motorized trolleys are available with two limit switches (or with one limit switch in case of dual configuration) that stops the trolley traverse right before the end stoppers. After the limit switch is activated it is only possible to back away the trolley from the limit switch activator. When trackline has no ends (it is a circular trackline), trolley does not have limit switches.

Climbing monorail trolley system, Roslift

Over-speed device

Spring-loaded hooks (jaw-clutch system) operating on centrifugal force will lock the wheels to the chassis, in case the trolley traverses too fast. Both wheels have their own over-speed device and they are capable to stop and keep the unit in any situation even if only one wheel over-speed device activates.

Electromechanical motor brake

Each motor has a electromechanical brake. The working principle is that the electric power forces the spring loaded brake to open. In case of electric power loss the spring will close the brake. The brake has enough power to stop and keep the unit in any situation.

Securing stopper

The securing stopper limits the opening of the lower wheel assembly in such way that it is impossible for the unit to fall out of the track.

Mechanical end stoppers

Mechanical end stoppers are installed at the end of the track line. The stoppers block the track end and therefore even in case of electrical limit switch failure prevents the unit running out of track

Every Roslift is tested on the factory

Dynamic test (traversing) with 25% overload

Static test with 50 % overload, which is 750kg

On site testing together with the cradle is done before commissioning

Tracks

Every joint has double system, if one fails other one will still keep it working.

- Two joint pins in each joint

- In RS110 track only one joint pin, but the bracket will work as double safety

Each bracket is bolted with two bolts to the track

The loads for each track are separately calculated according to EN1808 safety factors

For new product a risk factor sheet and declaration conformity is done

Horizontal monorail tracks

Even if the bolts would come loose, the trolley will stay on track as the axles are mounted from inside

Concealable tracks

The trolley body is bigger than the visible hole, so it is not possible to fit it through the track.

Roof Trolleys

The wire can be rigged safely from roof top

Armstrong by pulling the arm in

Roca by turning the arms to the rooftop